Soundproof Aluminum Tiles: Complete Guide

Soundproof aluminum tiles are advanced building materials designed to reduce noise transmission, improve acoustic comfort, and maintain structural durability. Combining high-strength aluminum surfaces with specialized acoustic cores, these tiles are ideal for residential, commercial, and industrial applications. This guide covers operational tips, core advantages, product highlights, and frequently asked questions, providing comprehensive information for buyers and users.

Noise pollution has become a major concern in modern buildings, affecting productivity, health, and comfort. Soundproof aluminum tiles offer a practical solution by integrating acoustic insulation with durable aluminum construction.

Applications include:

Recording studios and home theaters

Offices and conference rooms

Industrial facilities and factories

Restaurants, hotels, and commercial spaces

Public infrastructure such as airports and hospitals

Key Features:

High sound absorption and noise reduction

Lightweight and easy to install

Corrosion-resistant and durable

Fire-resistant options available

Long-lasting acoustic performance

Soundproof aluminum tiles provide a range of technical and functional benefits:

High-density insulation cores reduce sound transmission through walls, ceilings, and partitions.

Noise reduction coefficient (NRC): 0.6–0.9 depending on core type.

Effective for both airborne and impact noise.

Aluminum surface provides rigidity and mechanical protection.

Resistant to impact, deformation, and environmental wear.

Fire-rated acoustic cores available to meet Class A or B1 standards.

Flame-retardant materials reduce fire risks in residential and commercial buildings.

Corrosion-resistant aluminum surfaces withstand moisture, chemicals, and UV exposure.

Minimal maintenance required over decades of use.

Lightweight design and interlocking system allow for quick and precise installation.

Suitable for walls, ceilings, and partitions without heavy structural modifications.

| Feature | Description |

|---|---|

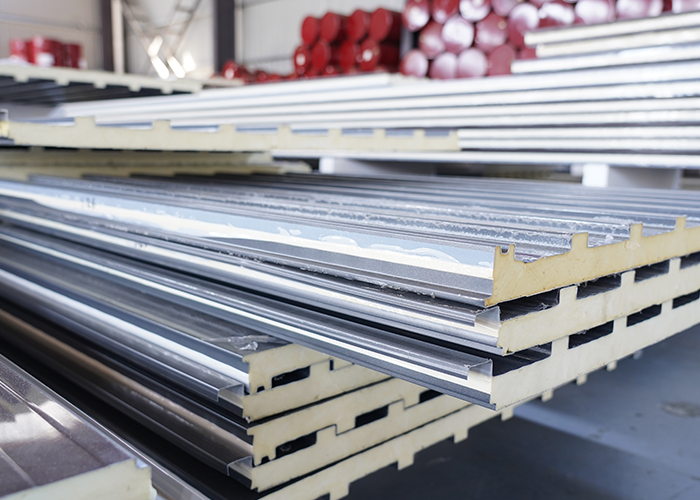

| Outer Layer | High-strength aluminum alloy providing structural support and corrosion resistance |

| Acoustic Core | Mineral wool, polyurethane, or foam-based cores absorbing sound efficiently |

| Inner Layer | Aluminum or composite sheet adding rigidity and moisture protection |

| Fasteners | Stainless steel screws, clips, or adhesive systems for secure installation |

| Surface Coatings | Powder-coated or anodized finishes for aesthetics and durability |

Optional Features:

Decorative finishes for interior design

Fire-rated cores for safety compliance

Custom sizes and thickness for specialized applications

Technical Specifications:

Tile Thickness: 30–100 mm

Noise Reduction Coefficient (NRC): 0.6–0.9

Fire Rating: Class A or B1

Weight: 8–15 kg/m²

Acoustic Performance: Effective for frequencies 125–4000 Hz

Service Life: 20–30 years

Proper handling and installation are critical to maximizing the acoustic and structural performance of soundproof aluminum tiles:

Ensure walls or ceilings are clean, dry, and level.

Remove dust, debris, or old insulation materials.

Install subframes or brackets if required.

Confirm alignment for consistent acoustic performance.

Begin installation from a corner or lower edge.

Interlock tiles securely using screws, clips, or adhesive systems.

Maintain consistent spacing to account for thermal expansion and vibration.

Seal all joints with acoustic sealant to prevent sound leakage.

Check edges and corners for proper alignment and coverage.

Conduct acoustic testing to verify performance.

Inspect fasteners and seals to ensure structural stability and optimal soundproofing.

Tips for Optimal Use:

Avoid overloading tiles beyond their mechanical specifications.

Use fire-rated cores in high-risk areas.

Regularly inspect for moisture or corrosion, especially in industrial environments.

Regular maintenance preserves acoustic efficiency and durability:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Surface Cleaning | Every 6–12 months | Mild detergent recommended; avoid abrasive tools |

| Fastener Inspection | Every 12 months | Tighten or replace screws/clips |

| Sealant Check | Every 12 months | Reapply if degraded to prevent sound leakage |

| Acoustic Performance Review | Every 2–3 years | Conduct sound testing for efficiency |

| Full Tile Replacement | Every 15–20 years | Replace tiles that are damaged or no longer effective |

Pro Tips: Avoid scratching or denting aluminum surfaces to maintain aesthetics and corrosion resistance.

| Problem | Possible Cause | Solution |

|---|---|---|

| Reduced Noise Reduction | Gaps in joints, damaged core, or improper installation | Reseal joints, replace damaged tiles, ensure proper installation |

| Surface Corrosion | Scratches or exposure to moisture | Clean and apply protective coating |

| Loose Tiles | Thermal expansion or improper fastening | Re-tighten screws, replace clips if needed |

| Fire Safety Concern | Non-rated cores or damage | Replace with certified fire-rated cores |

| Noise Transmission | Insufficient core density or gaps | Upgrade insulation core or add supplementary acoustic panels |

Preventive Measures: Conduct regular inspections of high-stress areas and moisture-prone zones to maintain acoustic and structural performance.

| Feature | Soundproof Aluminum Tiles | Traditional Materials (Drywall, Wood, Fiberglass) |

|---|---|---|

| Acoustic Performance | High NRC 0.6–0.9 | Moderate, often 0.4–0.6 |

| Fire Safety | Fire-rated cores available | Varies, often lower |

| Corrosion Resistance | Excellent | Poor in humid or industrial environments |

| Durability | 20–30 years with minimal maintenance | 10–15 years, higher maintenance |

| Installation | Lightweight and interlocking system | Labor-intensive and heavy |

| Energy Efficiency | Additional thermal insulation | Limited or none |

These tiles outperform conventional soundproofing materials in terms of durability, acoustic efficiency, fire safety, and installation convenience.

Worker Safety: Use gloves, helmets, and fall protection during installation.

Fire Compliance: Ensure cores meet local fire safety standards.

Structural Safety: Verify support structures can bear tile weight and vibration.

Environmental Compliance: Low-VOC coatings and recyclable materials available.

Q1: Can these tiles significantly reduce noise in industrial environments?

A1: Yes, with NRC up to 0.9, they reduce both airborne and impact noise effectively.

Q2: How long do soundproof aluminum tiles last?

A2: 20–30 years with proper installation and maintenance.

Q3: Are they fire-resistant?

A3: Yes, fire-rated cores are available to meet Class A or B1 standards.

Q4: Can these tiles be used outdoors?

A4: Yes, aluminum surfaces resist corrosion and UV exposure, making them suitable for exterior applications.

Q5: Are they compatible with existing walls and ceilings?

A5: Yes, lightweight design and interlocking system allow easy retrofitting.

Soundproof aluminum tiles are a modern solution for reducing noise while providing structural durability and fire safety. With superior acoustic performance, easy installation, and long-term maintenance, these tiles are ideal for a wide range of applications, from residential and commercial spaces to industrial facilities. Proper operational practices, regular maintenance, and adherence to safety standards ensure maximum performance and longevity.

Contact Person: Wang Ye

Tel: +86 158 33457666

Email: 944713874@qq.com

Address: South side of Yuxin Highway, Dongxian Village, Yahongqiao Town, Yutian County, Tangshan City, Hebei Province

Copyright © 2025 Tangshan Juze Technology Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.