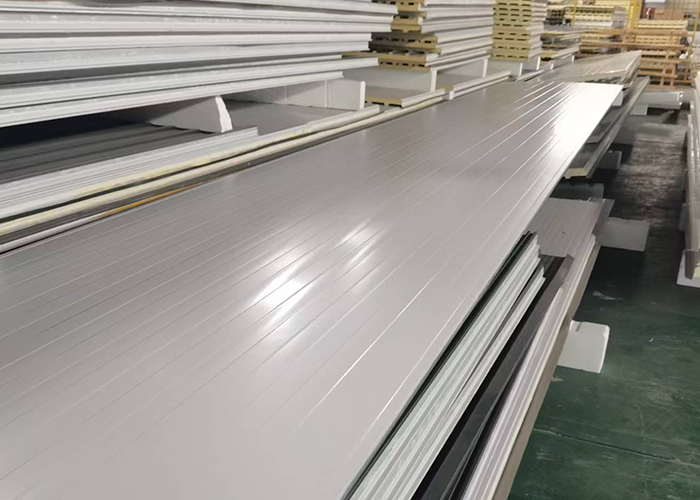

Industrial Roof Aluminum Tiles

Durable, Energy-Efficient, and Weather-Resistant Roofing Solutions for Industrial Applications

Industrial roof aluminum tiles are engineered for high-performance roofing in industrial and commercial buildings. Made from premium aluminum alloy with protective coatings, these tiles combine durability, corrosion resistance, and thermal insulation to provide long-lasting roofing solutions.

Designed to withstand extreme weather conditions, heavy loads, and industrial environments, they are ideal for factories, warehouses, workshops, and commercial buildings. The tiles are lightweight, easy to install, and low-maintenance, making them a cost-effective solution for modern industrial roofing projects.

Corrosion Resistance: Special coatings protect against rust, UV exposure, and chemical corrosion.

Thermal Insulation: Reduces heat transfer and helps maintain indoor temperature stability.

Fire Resistance: Complies with international fire safety standards.

Lightweight and Strong: Easy to handle and install while providing high structural strength.

Weatherproof: Resistant to rain, wind, and snow.

Long Lifespan: Durable materials ensure years of reliable performance.

| Layer | Material | Function |

|---|---|---|

| Top Coating | PVDF / Polyester | UV protection, color retention, corrosion resistance |

| Aluminum Alloy Sheet | 3005 or 5052 grade | Structural strength and durability |

| Primer Layer | Zinc / Chromate | Enhances adhesion and corrosion protection |

| Back Coating | Polyester | Protects underside from moisture and wear |

| Parameter | Specification / Range |

|---|---|

| Material | Aluminum Alloy 3005 / 5052 |

| Thickness | 0.4–1.2 mm |

| Tile Width | 800–1200 mm |

| Tile Length | 1.0–6.0 m (customizable) |

| Coating Type | PVDF / Polyester / Fluorocarbon |

| Fire Rating | Class A / UL 790 |

| Weight | 3–8 kg/m² depending on thickness |

| Surface Finish | Smooth, corrugated, or embossed |

| Color Options | Standard Silver / Custom RAL colors available |

Industrial roof aluminum tiles are manufactured according to international quality and safety standards, ensuring reliable performance for industrial applications:

| Certification | Purpose | Standard |

|---|---|---|

| ISO 9001 | Quality management | Ensures consistent manufacturing quality |

| ISO 14001 | Environmental management | Confirms eco-friendly production |

| CE Mark | European conformity | Compliance with EU safety and performance requirements |

| ASTM B209 | Aluminum sheet standard | Confirms material strength and durability |

| UL 790 | Fire safety | Provides fire-resistant classification |

These certifications guarantee that the tiles meet global building codes and are suitable for international markets.

Industrial roof aluminum tiles are versatile and can be applied in multiple industrial and commercial scenarios:

Warehouses: Lightweight, durable roofing with excellent thermal insulation.

Factories: Resistant to chemicals, heat, and mechanical impact.

Workshops: Easy installation and low maintenance for high-traffic environments.

Commercial Buildings: Modern, aesthetic roofing solution with long lifespan.

Industrial Renovation Projects: Ideal for replacing old or damaged roofing with minimal structural modifications.

Tip: Choose tile thickness and coating type according to local weather, fire safety, and load requirements.

Proper installation ensures maximum performance and durability:

Surface Preparation: Ensure roof framework is clean, level, and structurally sound.

Measuring and Cutting: Measure panels carefully and cut using metal shears or circular saws.

Positioning: Start from the bottom edge and work upwards, overlapping panels as specified.

Fastening: Use corrosion-resistant screws and fasteners with rubber washers.

Sealing: Seal seams with aluminum tape or silicone sealant to prevent water ingress.

Inspection: Verify alignment, fasteners, and sealing for complete coverage.

Tip: Always follow local building codes for safety and warranty compliance.

To maintain performance and appearance:

Routine Cleaning: Remove dirt, dust, and debris using a soft brush or water spray.

Avoid Abrasives: Do not use harsh chemicals or abrasive pads that may damage coatings.

Inspection: Check for scratches, dents, or loose fasteners every 6–12 months.

Repair: Minor scratches can be touched up with aluminum paint; replace damaged panels if necessary.

Preventive Measures: Trim nearby tree branches and clean gutters to prevent damage or water accumulation.

Proper maintenance extends the lifespan of Aluminum roof tiles and ensures energy efficiency.

Industrial roof aluminum tiles are carefully packaged to avoid damage during transportation:

| Packaging Type | Details |

|---|---|

| Standard Bundle | 20–50 tiles per bundle, protected with kraft paper and shrink wrap |

| Palletized | Wooden or metal pallets for ease of handling |

| Protective Layer | Foam or cardboard separators to prevent scratching |

| Custom Packaging | Available for international shipping or large orders |

Tip: Inspect tiles upon delivery for any visible damage and store in a dry, ventilated area until installation.

| Feature | Benefit |

|---|---|

| Lightweight | Reduces structural load and simplifies installation |

| Corrosion Resistant | Long-lasting performance in industrial environments |

| Thermal Insulation | Reduces energy costs and maintains stable indoor temperature |

| Fire Resistant | Complies with global fire safety standards |

| Aesthetic Appearance | Smooth, corrugated, or embossed finishes for modern industrial look |

| Low Maintenance | Minimal cleaning and upkeep required |

Industrial roof aluminum tiles provide a durable, energy-efficient, and cost-effective roofing solution for industrial and commercial projects worldwide. With international certifications, superior thermal insulation, fire resistance, and low maintenance, they ensure long-lasting performance and structural safety. Proper installation, regular inspection, and maintenance maximize tile lifespan and efficiency, making these aluminum tiles a preferred choice for modern industrial roofing solutions.

RELATED

RELATED

Contact Person: Wang Ye

Tel: +86 158 33457666

Email: 944713874@qq.com

Address: South side of Yuxin Highway, Dongxian Village, Yahongqiao Town, Yutian County, Tangshan City, Hebei Province

Copyright © 2025 Tangshan Juze Technology Co., Ltd. All rights reserved

This website uses cookies to ensure you get the best experience on our website.